For the high end of threat levels, we utilize the only certified armor plate manufacturer in the market today. Competitors of this manufacturer use steel renamed as “wear plate” as their version of armor plate. Wear plate is used in the mining industry to protect dump truck beds and bucket liners. This material is manufactured from start to finish to meet MIL-A-46100D and MIL-A-46177B Armor Plate as per the rigorous U.S. Military’s Armor Specifications. It is tested at Aberdeen Proving Grounds to meet the military standards. Once the product conforms to the MIL standards, it must pass additional ballistic testing to meet the Underwriters Laboratory and National Institute of Justice standards. These standards are met through independent tests at certified laboratories.

Kevlar, (a registered product of DuPont) and / or Spectra, (a registered product of Allied Signal) is utilized when total overall weight is a manufacturing concern or requirement. These lightweight armor materials can be laminated to varying thicknesses to deflect the high end of threat levels as well.

For our glass armor, we use a lightweight combination of laminated glass, chemically strengthened glass and lightweight polymer compounds. This product called “glass clad polycarbonate” provides increased ballistic protection over what the industry used to call “bulletproof glass.” Glass clad polycarbonate weighs approximately one third of the total weight and is one third as thick as the old bulletproof glass. This bulletproof glass also offers significantly higher light transmission, and significantly less distortion over the old glass. The end result of this product is years of service without the burden of the higher weight while still maintaining superior ballistic protection.

The threat level of protection you seek can be determined from the various domestic and international standards, or bulletproof protection can be custom crafted to defeat a specific threat that you have identified.

Relative Guide To Bullet Resisting Threat Levels

| Level | Weapon | Caliber | Weight (G) | Range (M) | Speed (M/S) | # Shots |

|---|---|---|---|---|---|---|

| B1 |  |

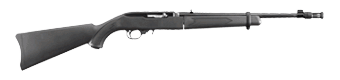

.22LR | 2.6 ± 0.1 | 10.00 ± 0.5 | 360 ± 10 |  |

| B2 |  |

9mm Luger | 8.0 ± 0.1 | 5.00 ± 0.5 | 400 ± 10 |  |

| B3 |  |

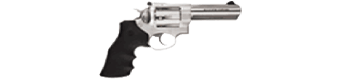

.357 Magnum | 10.2 ± 0.1 | 5.00 ± 0.5 | 430 ± 10 |  |

| B4 |  |

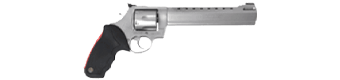

.44 Magnum | 15.6 ± 0.1 | 5.00 ± 0.5 | 440 ± 10 |  |

| B5 |  |

5.56x45mm / SS109 & M193 | 4.0 ± 0.1 | 10.00 ± 0.5 | 950 ± 10 |  |

| B6 |  |

7.62 x 51mm / M80 Nato Ball | 9.5 ± 0.1 | 10.00 ± 0.5 | 830 ± 10 |  |

| B7 |  |

7.62 x 51mm AP | 9.8 ± 0.1 | 10.00 ± 0.5 | 820 ± 10 |  |